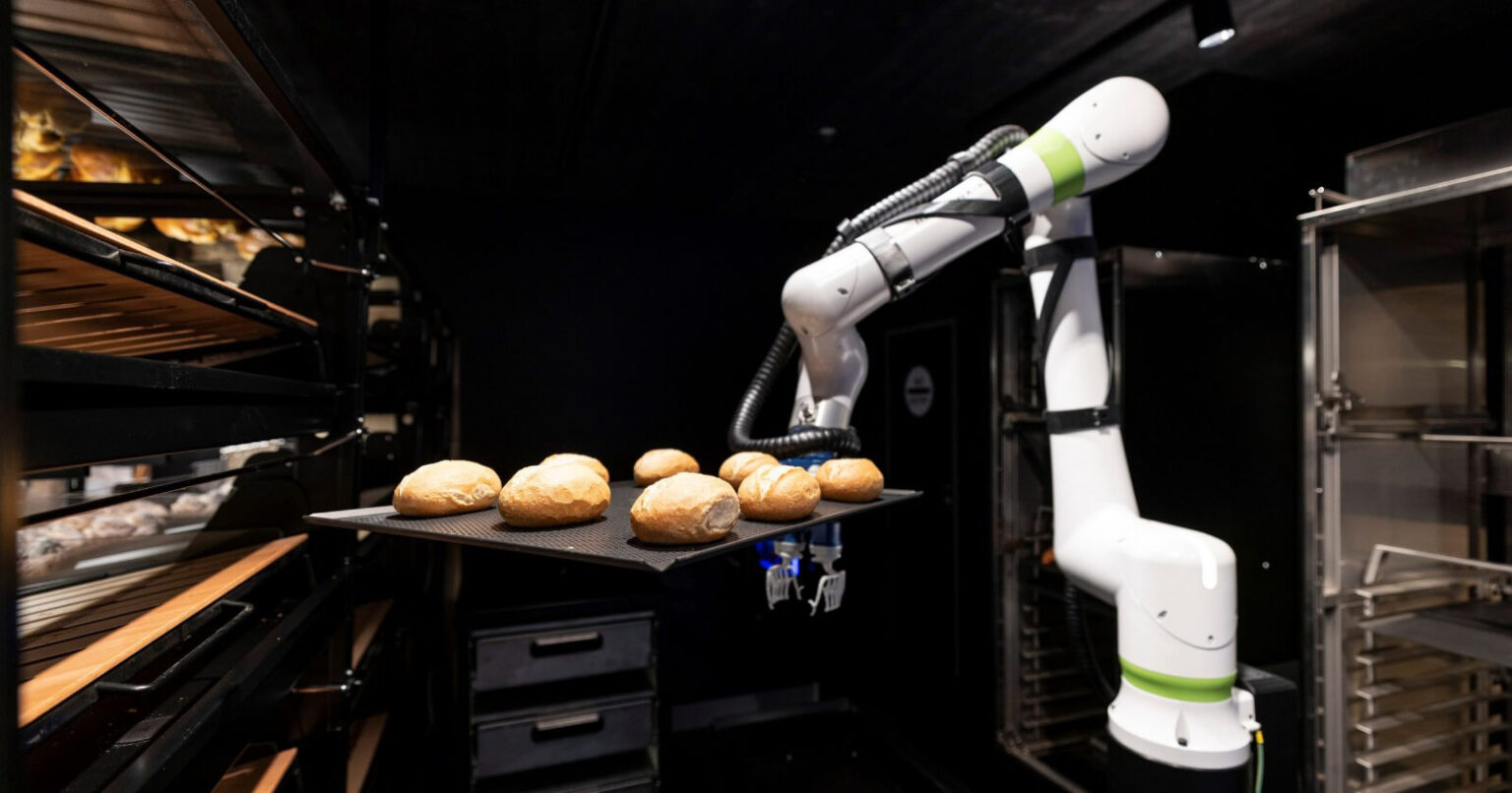

Bakisto, which performs important work steps such as loading the bakery tray, placing the tray in the oven, removing it from the oven and stocking the display cases, also plays a key role in combating food waste thanks to its artificial intelligence. The robot calculates how much bread, croissants and pastries will be in demand during the day, then prepares the baked goods and takes them out of the oven at the right time.

Although they come from industry, robots are now used in laundries, farms and fields, and are now starting to work in bakeries and pastry shops. Japanese automation giant FANUC, bakery manufacturer WIESHEU and retail specialist Wanzl have joined forces against food waste, which has reached higher levels with the growing world population, and developed the automated collaborative robot Bakisto. Bakisto brings a higher level of reliability to the cooking process in places like supermarkets and bakeries where ovens are located, and reduces food waste thanks to its efficiency.

Bakisto prevents food waste with its artificial intelligence system

“Using artificial intelligence, Bakisto calculates how much bread, croissants and pastries will be in demand during the day, then prepares the baked goods and takes them out of the oven at the right time. Composed of three interconnected systems, Bakisto uses artificial intelligence to estimate the daily quantity requirements for baked goods based on historical data and existing stocks, and when the most intensive baking is needed to meet demand. Once this information has been entered into the system, the robot takes the baking trays loaded with frozen bakery products from the cooling unit and pushes them onto the trolley, which runs on rails in front of the preheated oven. The TrayMotion loading system pulls the loaded trays in so that the baking process can begin. After baking, the system pushes the baking trays back onto the trolley, which moves to the side, allowing the baked goods to cool and freeing up space for the next production run. The robot then fills BakeOff’s predefined bays with finished and cooled baked goods. The artificial intelligence part continuously optimizes the process of transferring new data.”